BOPP LLDPE HDPE LDPE PE PP recycling granulating machine is special equipment for the plastic film/bags recycling granulating, it equipped with compacting machine which pre-compact the film into smaller granules, then easily feed into screw barrel extruder, high efficiency improve production capacity.

Product Description

The ACC series compacting and pelletizing system combines function of crushing, compacting, plasticization and pelletizing to one step.applied in the plastics recycling and pelletizing process.

ACC system is a reliable and efficiency solution for plastics films, raffias, filaments, bags, woven bags and foaming materials re-pelletizing.

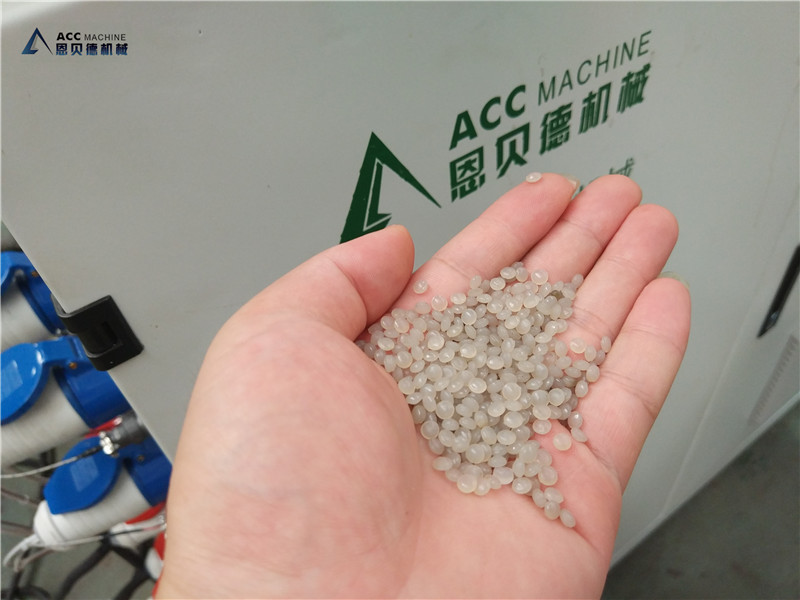

Final productions produced by acs system are in the form of pellets/ granules, can directly put into the production line for film blowing, pipe extrusion and plastics injection, etc.

Main information

SPECIFICATIONS | |

Machine Model | ACC |

Target Recycled Material | HDPE, LDPE, PP, BOPP, CPP, OPP, PA, PC, PS, PU, ABS |

Final Product Shape | Particles,pellets |

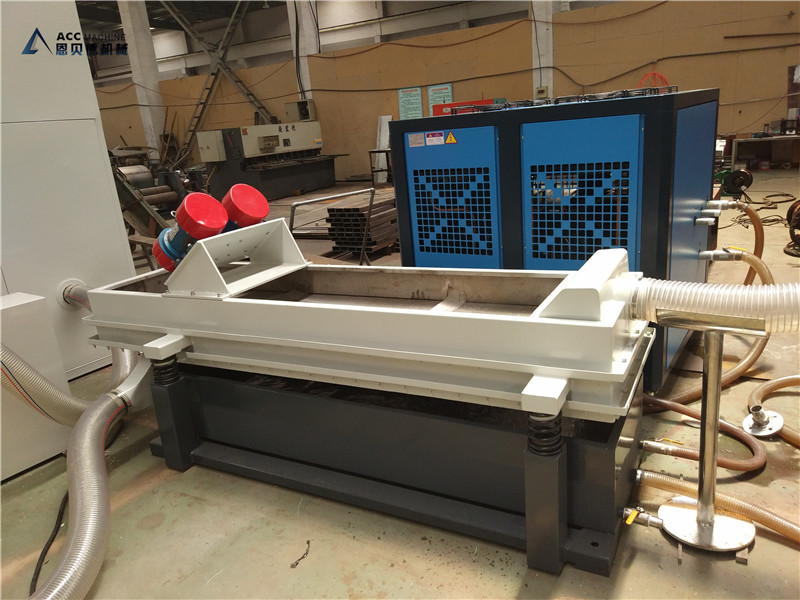

System composition | Belt Conveyor, Cutting Compactor, Single Screw Extruder, Filtration, Pelletizer, Water Cooling Device, Dehydration Section, Conveyor Fan, Product Silo. |

Output Range | 150kg/h-800kg/h |

Feeding Device | Belt Conveyor (Standard), Roll Hauling off device (Optional) |

Compactor Volume | 300L-1400L |

Diameter of screw | 80mm-180mm (Standard) |

Material of screw | 38CrMoAlA (SACM-645), Bimetal (Optional) |

L/D of screw | 31/1, 32/1, 34/1, 36/1 (According to the characteristics of recycling) |

Heater of barrel | Ceramic heater or Far-infrared heater |

Cooling of Barrel | Air cooling of fans through blowers |

Vacuum deashing exhaust | Two Double-zone vacuum degassing system (Standard) |

Pelletizing type | Water-ring pelletizing/ water-strands pelletizing/ Under-water pelletizing |

Voltage Standard | According to the Voltage of the Customer's Location |

Optioanl device | Metal detector, Roll hualing off device, Masterbatch and additives feeder |

Warranty | 13 months from the date of bill of lading |

Technical services | project design, factory construction, installation and recommendations, commissioning |

All machine model

Model | Screw Diameter(mm) | L/D | Extruder motor (kw) | Output capacity (kg/h) |

ACC-85 | 85 | 33-36 | AC 55 | 160-200 |

ACC-100 | 100 | 33-36 | AC 110 | 200-300 |

ACC-120 | 120 | 33-36 | AC 132 | 300-400 |

ACC-140 | 140 | 33-36 | AC 185 | 400-500 |

ACC-160 | 160 | 33-36 | AC 250 | 500-800 |