PVC WPC foam board extrusion line/WPC solid door board making machine/WPC furniture panel production line: WPC solid door board making machine for 30-45mm thickness e is used for making 30-45mm solid WPC foam board for door panel, it uses PVC and wood fiber as raw material, by semi-crust or full-crust foaming technology, to make WPC solid boards/panels with low density for 0.45-0.8gram/cm3, the WPC foam boards are widely used for making furniture panel, construction formwork, partition wall....

Product Description

Product Description

1. Description of PVC foam Crust Board

PVC foam board is also called Chevron board and Andy board, and its chemical composition is polyvinyl chloride (Polyvinyl chloride), so it is also called foam polyvinyl chloride board. Widely used in passenger cars, train car roofs, box cores, interior decoration panels, building exterior wall panels, interior decoration panels, office, residential, and public building partitions, commercial decoration racks, and clean room panels , Ceiling panels, screen printing, computer lettering, advertising signs, exhibition boards, sign boards, photo album boards and other industries and chemical anti-corrosion engineering, thermoformed parts, cold storage boards, special cold insulation engineering, environmental protection board molds, sports equipment, breeding materials , Seaside moisture-proof facilities, water-resistant materials, art materials and various lightweight partitions instead of glass ceilings.

2. Advantages of our machine

Our PVC foam board machine includes the special Twin-screw extruder, mould and other auxiliary machines. We use twin-screw extruder with compact structure, superior performance. Besides the screw and barrel and die are designed by our company and made in world famous manufacturers. And use the high-performance alloy steel for professional processing. So the machine has the advantages of uniform plasticizing, stable extrusion, high output, and long

life. We can supply you the best material formulation and all of technology. We have several thousand kinds of formula through 15 years’ researches. PVC or WPC foam board production line with big output, stable extrusion, high foaming, good and wear-resisting surface and so on.

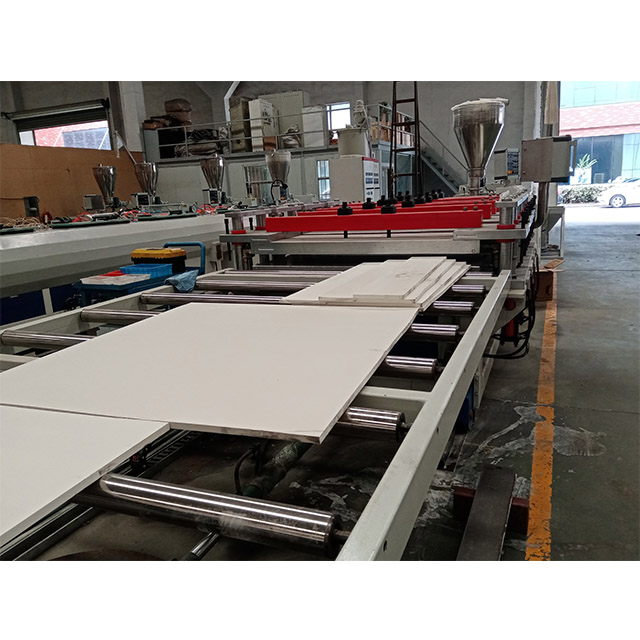

3. Flow chart

Mixer→Loader→Extruder→Mould→Calibration platform→Cooling bracket→Hauling machine→Cutting machine(With dust collector)→Stacker

→Packing→Crusher(for waste material) →Pulverizer(For recycled material)

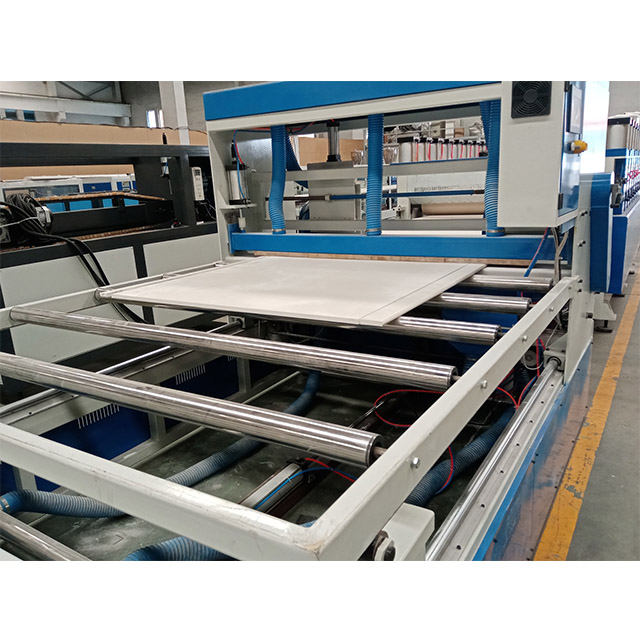

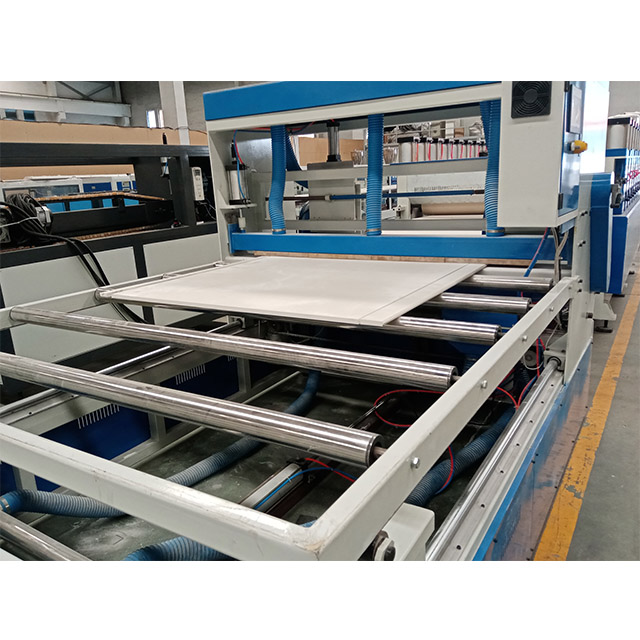

Machine Pictures

Machine Pictures

Technical parameters

Technical parameters

| Model | ACC-80 |

| Extruder | SJSZ-80/156 |

| Main motor | 55kw |

| Thickness | 3-20 mm |

| Heating power | 24 kw |

| Capacity | 300-400kg/h |