wood-plastic floor means that the compounding, devolatilization, and product extrusion molding of wood-plastic composite materials are completed in different equipment, that is, after the raw materials are mixed according to a certain formula, wood-plastic particles are formed in the middle, and then they are extruded into this process of wood plastic flooring. At present, the two-step method is widely used. Generally, it is pelletized with a cone twin extruder or a flat twin extruder, and then a cone twin or single screw extruder is used to extrude molded products. It is mainly used for indoor and outdoor floors, guardrails, and pallets. Such as PE&PP wood-plastic products extrusion molding.

Product Description

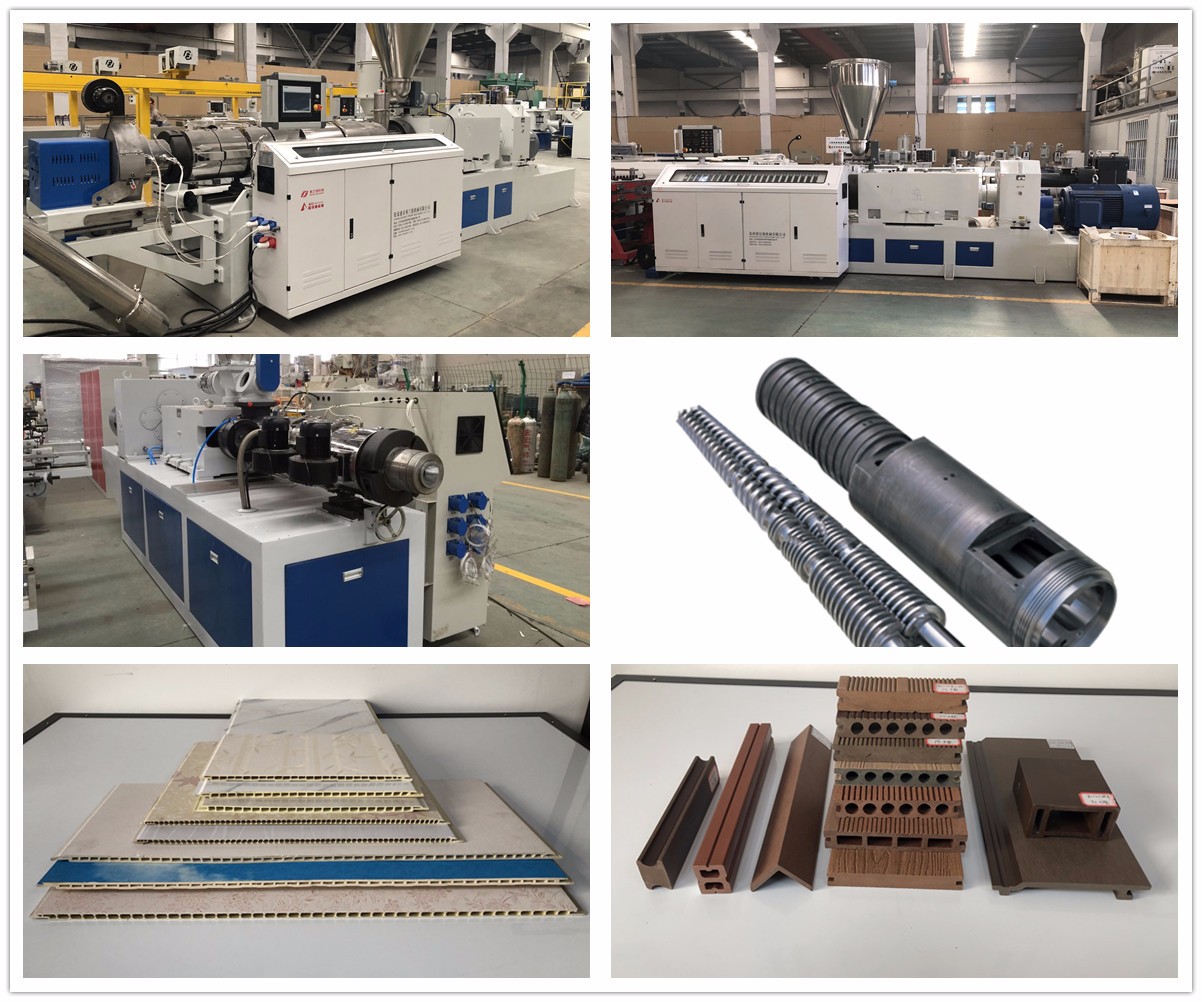

The single-screw plastic profile extruder production line is mainly used to produce PVC, PC, PE, and other plastic profile products. The production line consists of single-screw plastic extruder, vacuum setting table, tractor, automatic cutting machine, material rack, etc. Equipped with different molds, it can produce plastic profiles, door and window profiles, container sealing strips, plates, bars, ceilings and other products. The production process is simple, the output is high, the quality is stable, and the cost is low.

Profile extrusion molding equipment

1. Extruder for profile production: single-screw extruder, which uses pellets to produce profiled materials, and products with small cross-sectional area. Generally, the model of the extruder is determined according to the size of the product.

2. Profile head: The head is the main part of product molding. Its function is to continuously and uniformly transform the cylindrical melt provided by the extruder into a well-plasticized parison that is similar to the channel section and geometry, and then through other processes such as cooling and shaping to obtain a profile with good performance. Products

3. Vacuum shaping device: It uses indirect water cooling to cool and shape the high-temperature molten profile extruded from the die. The vacuum setting sleeve is composed of two parts, a vacuum setting zone and a cooling zone with adsorption slits on the inner wall, and the two zones are alternated. Negative pressure is generated around the vacuum zone, so that the outer wall of the profile is in close contact with the inner wall of the vacuum setting sleeve, so that the profile can be cooled and shaped;

4. Traction device: a crawler traction device can be used. If the shape of the rubber block on the track is processed to be consistent with the contour of the traction profile, the traction effect will be better;

5. Cutting device: sawing, shearing and grinding off. Such as circular saw cutting machine, cylinder type shearing machine, rotary shearing machine and grinding wheel grinding machine, etc.

Machine Parameters

Plastic material | recyccled PP/PE plastic |

Wood material | wood powder from rice husk/straw,wheat husk/straw,wood sawdust,wastage wood |

Percentage of plastic | 25-30% |

Percentage of wood powder | 50-70% |

Final product | WPC decking, WPC wall cladding, WPC pergola profile,WPC post, WPC fence profile, and other WPC construction profiles |

Production process | raw material--mixing--granulation--extrusion and molding--surface treatment |

Machine details