wood-plastic floor means that the compounding, devolatilization, and product extrusion molding of wood-plastic composite materials are completed in different equipment, that is, after the raw materials are mixed according to a certain formula, wood-plastic particles are formed in the middle, and then they are extruded into this process of wood plastic flooring. At present, the two-step method is widely used. Generally, it is pelletized with a cone twin extruder or a flat twin extruder, and then a cone twin or single screw extruder is used to extrude molded products. It is mainly used for indoor and outdoor floors, guardrails, and pallets. Such as PE&PP wood-plastic products extrusion molding.

Product Description

The wood-plastic door is made by mixing ultra-fine wood powder and polymer resin through a molding process. It has the excellent characteristics of wood and plastic, and the products produced achieve the effect of real wood imitation. Since the raw materials used and the production process do not use glue to bond, it will not produce harmful substances such as formaldehyde, benzene, ammonia, trichloroethylene, and is a new green and environmentally friendly material that replaces traditional wood.

Configuration list

Configuration list

| 1 | Screw feeder | 1 set |

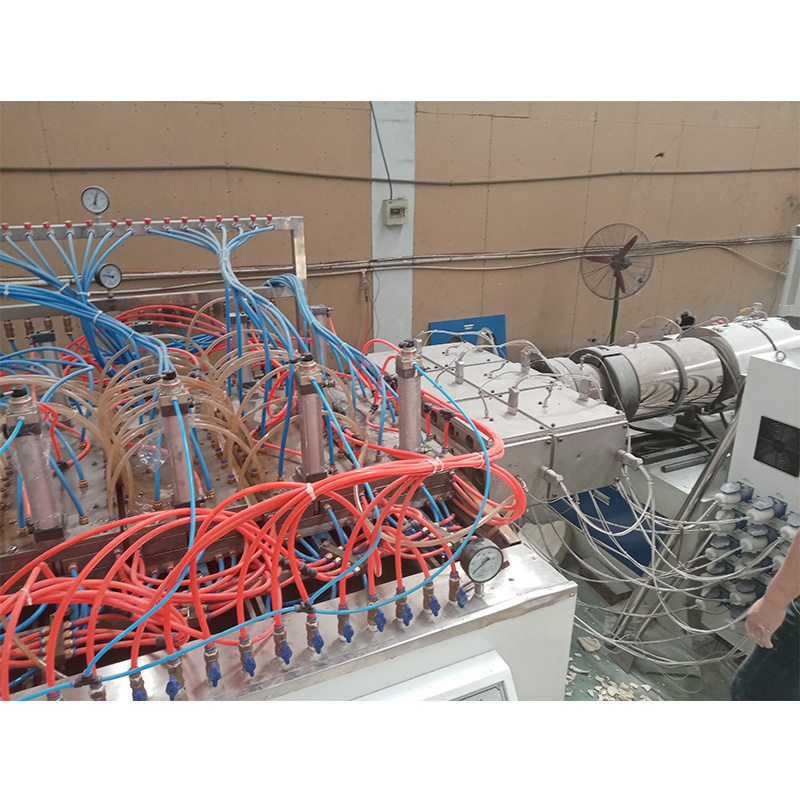

| 2 | SJSZ80/156 twin screw extruder | 1 set |

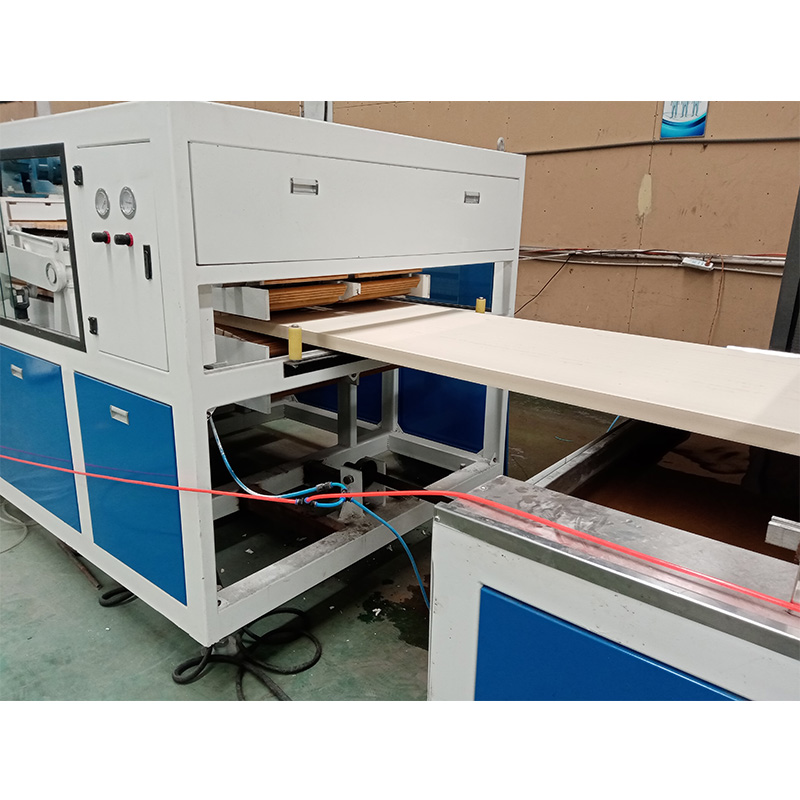

| 3 | Mold | 1 set |

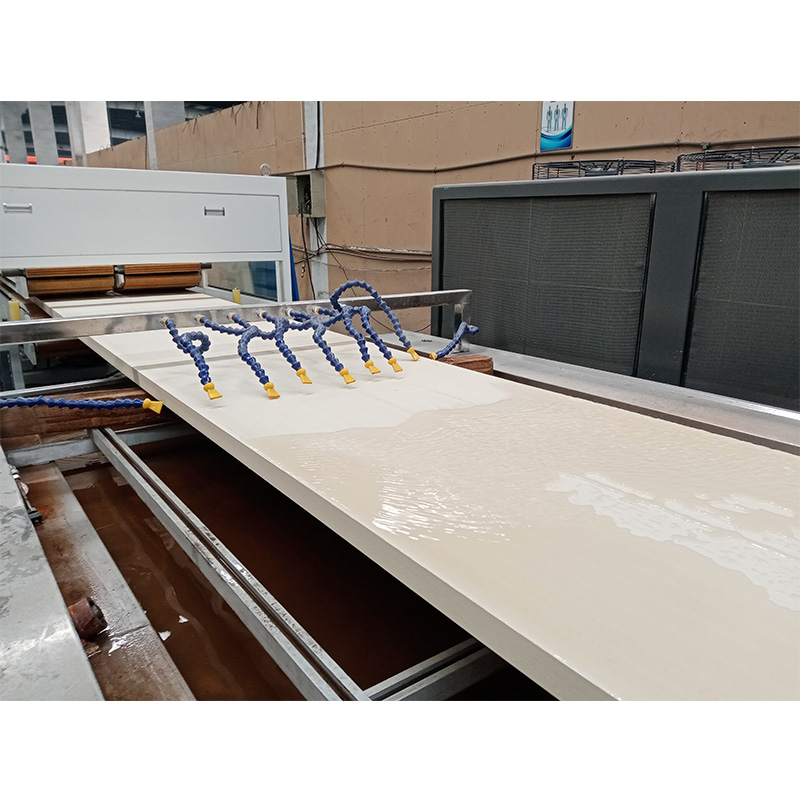

| 4 | Calibration table | 1 set |

| 5 | Haul-off machine | 1 set |

| 6 | Cutter | 1 set |

| 7 | Stacker | 1 set |

Machine details

Machine details

Packing and delivery

Packing and delivery